The Side Boom Truck Load Moment Indicator (LMI) is a critical safety device used extensively in industries like construction and maintenance. It provides real-time monitoring, allowing operators to assess the load's weight and the machine's stability during lifting operations. By continuously evaluating parameters such as load weight and boom angle, the LMI ensures safe lifting practices and minimizes risks like overloading or tipping. This makes it an indispensable tool for maintaining safety on work sites.

Equipped with advanced warning capabilities, the Side Boom Crane LMI alert operators immediately to unsafe conditions. This proactive approach significantly reduces the likelihood of accidents, equipment damage, and workflow interruptions. By promoting safe and efficient operations, these indicators not only enhance safety but also boost overall productivity in side boom truck and crane operations.

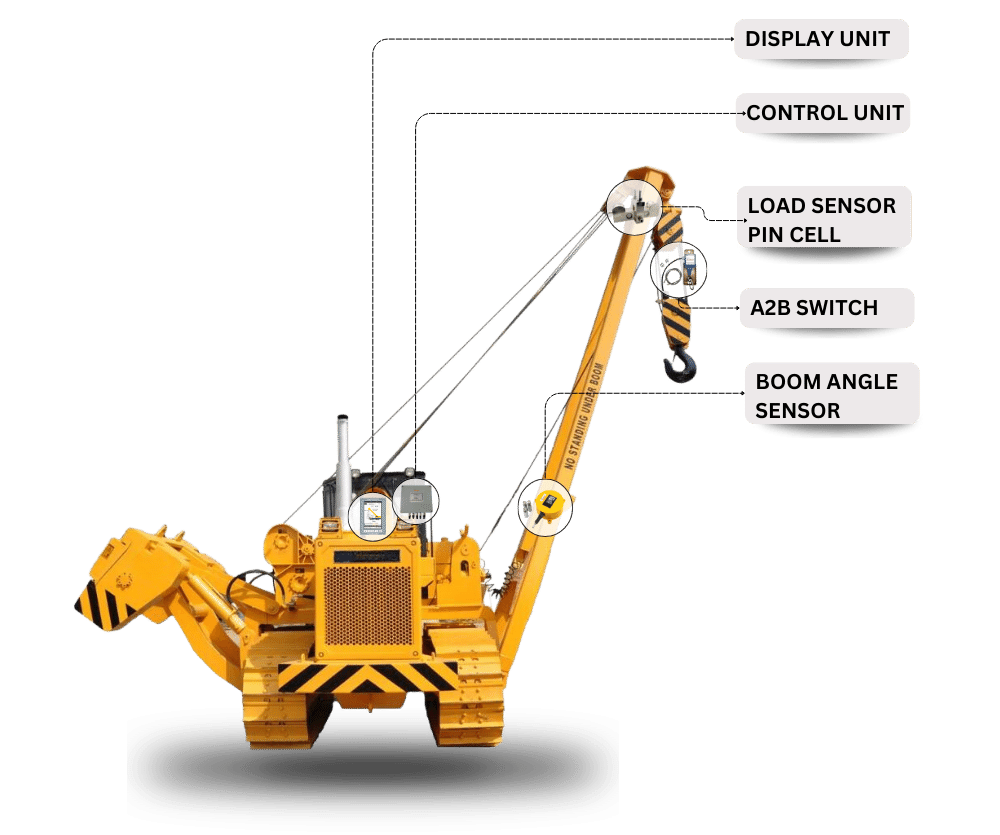

Components of Side Boom Truck LMI

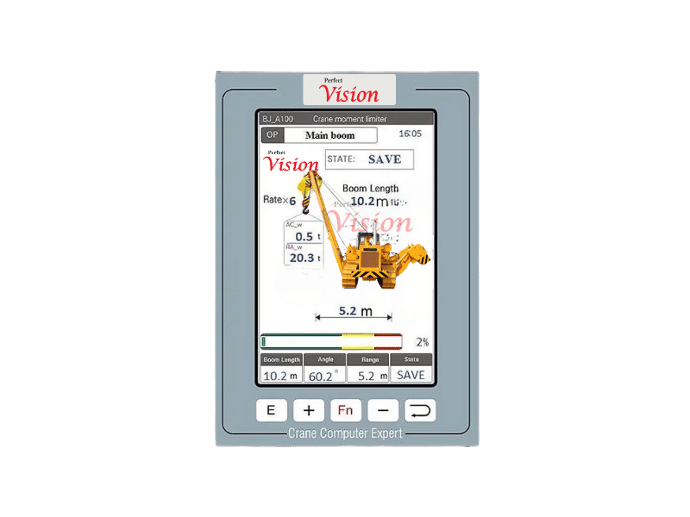

Display & Control Unit

Interface for operators to monitor load conditions and control the Side Boom Truck LMI, providing real-time data and alerts.

Boom Angle Sensor

Measures boom angle to calculate load moments accurately and prevent overloading or tipping hazards.

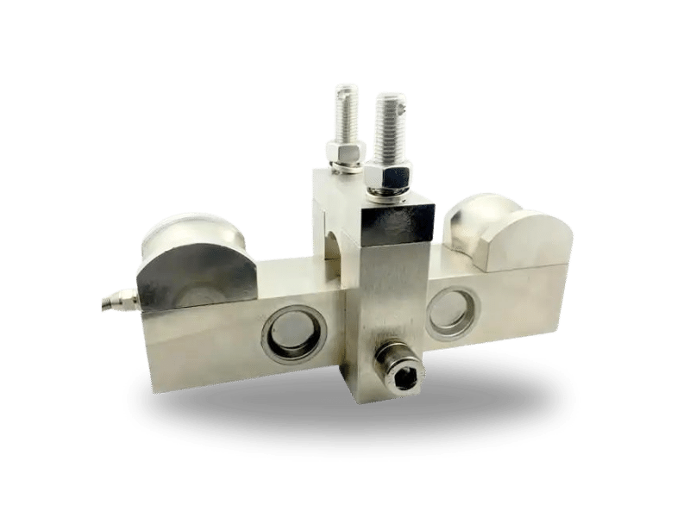

Load Sensor PIN CELL

Measures load weight for accurate load moment calculations and safe lifting operations.

A2B Switch

Safety switch to engage before crane operation, directing all functions to the boom for enhanced safety.

Junction Box 1 & 2

Connection points for various LMI components, facilitating proper wiring and integration.

Features of Side Boom Truck LMI

Constantly tracks load conditions and machine stability during lifting operations.

Issues immediate alerts and warnings when unsafe conditions are detected.

Regularly evaluates factors like load weight and boom angle to prevent overloading and tipping hazards.

Provides operators with quick feedback to prevent accidents and equipment damage.

Promotes adherence to safe lifting protocols, reducing the risk of accidents on the job site.

Understanding Functionalities of Side Boom Crane LMI

The Side Boom Crane Load Moment Indicator (LMI) operates by continuously monitoring essential parameters like load weight, boom angle, and machine stability during lifting tasks. It relies on sensors installed on the side boom truck, including load sensors and boom angle sensors, to gather real-time data on the load’s weight and the angle of the boom. This data is then processed by the LMI’s control unit, which calculates load moments and evaluates the truck’s stability. If the LMI detects that the load is nearing or surpassing safe operating thresholds, it promptly alerts the operator, urging them to take corrective measures. By providing instant feedback and warnings, the Side Boom Truck LMI plays a crucial role in preventing accidents and ensuring the safe and effective execution of lifting operations across various industrial environments.

Frequently Asked Questions & Answers

A Side Boom Truck Load Moment Indicator (LMI) is a safety device that monitors load weight, boom angle, and machine stability in real-time during lifting operations. It helps operators prevent overloading and tipping by providing immediate alerts when operating limits are exceeded.

The LMI monitors key parameters like load weight and boom angle, issuing visual and audible alerts when unsafe conditions are detected. This enables operators to take corrective action and prevents accidents during lifting operations.

Real-time monitoring allows operators to receive continuous feedback on load conditions, boom angle, and machine stability. This immediate data helps operators adjust lifting operations to stay within safe limits.

By monitoring the boom angle and load weight in real-time, the LMI helps prevent tipping by alerting the operator when the boom reaches angles or loads that could compromise the truck’s stability.

Yes, the LMI helps optimize operations by ensuring that the truck operates within safe limits, minimizing downtime caused by accidents or equipment damage, and improving overall productivity.

Yes, regular maintenance and inspection of the LMI system are crucial to ensure its accuracy and reliability. Maintenance schedules typically follow the truck’s service intervals.

Contact our experts now !

Let’s discuss how our solutions can make your workplace safer and more secure. Your safety is our priority.